|

Specification / Documentation Support

Working with the client's technical team we add additional design and engineering resources to produce specifications for the design of components and assemblies.

Bayly’s engineers are experienced at preparing documentation to support client’s efforts in Military, Medical (GMP) and general QA environments. This includes specifications for procurement, materials, manufacturing, testing and inspection processes. Flowcharts are useful to describe the key operations in manufacturing processes and provide the framework, or map, of the manufacturing operation.

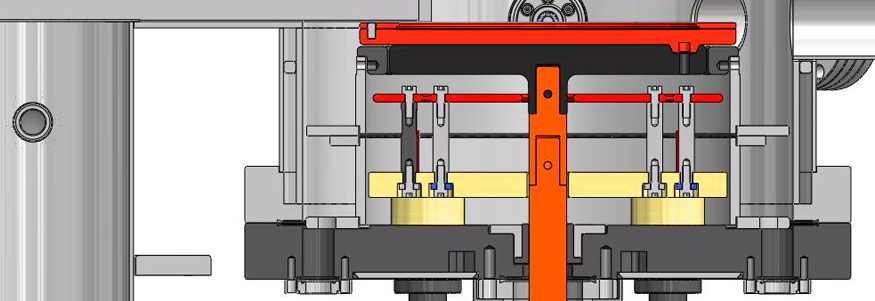

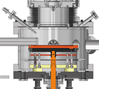

CAD design, Modelling and Animation

3D CAD modelling services are available from Bayly in CAD packages including Solidworks, NX and ProEngineer.

Bayly provides animation services to clients using CAD and Maya animation and rendering systems. For specialist animation requirements, Bayly has a network of associates that work with our team to deliver exactly what is required.

Virtual Prototyping

Is a term that is commonly being used to describe the range of software based simulation and analysis tools that are available to assist in engineering processes today.

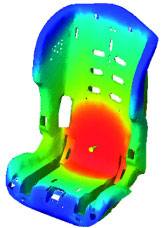

Stress Analysis

Bayly uses Ansys FEA software tools to simulate the effect of mechanical, shock, vibration and thermal loads on assemblies, components and systems in support of your design, engineering and prototyping efforts.

The type of simulation available through Bayly’s team includes linear and non-linear analysis.

Bayly’s engineers are also experienced in undertaking traditional theoretical and calculation based analysis in support and in confirmation of simulated and actual test results.

Dynamic Simulation

Bayly uses MSC.VisualNastran software for undertaking analysis of dynamic systems and is able to simulate and animate the behaviour of the systems, the loads generated and analyse the stresses in the components of the system.

Moldflow Simulation

Moldflow is used to check the design of plastic moulded components by simulating the injection moulding process and plastic flow inside injection moulding tooling.

This type of analysis provides indications of part quality, optimum gate positions and allows for design refinements to be undertaken to the component design to optimise the filling and moulding process.

System Simulation

Using software tools like Arena Simulation, Bayly are able to model and simulate virtually any type of system from simple continuous processes through to complicated batch and packaging process.

Statistical variations and what if scenarios are able to be simulated and the system response simulated and optimised before the expense of establishing the process is undertaken.

By varying the characteristics of elements of the system, we are able to simulate the overall outcomes and test the system’s sensitivity to variations in the designed process.

For specialist simulation applications, Bayly’s network of associates supports our activities.

Design Review & Verification Services

Bayly provides design review and verification services as an independent service to clients.

Verification of designs, products and equipments to established Australian and International standards can be undertaken in a wide variety of fields within the mechanical engineering discipline.

These activities help clients reduce their risk to flow on outcomes from inadvertent errors and oversights.

Bayly undertakes FMECA projects for clients to document the risk management outcomes and activities on engineering projects. Bayly’s FMECA process is derived from the requirements of the International IEC 60812 standard and can adapt the FMECA process to conform to other relevant standards used in military, medical and automotive industries.

|