|

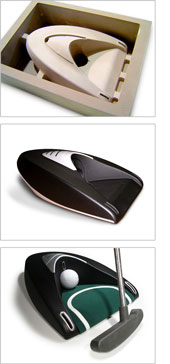

Prototyping, prototyping and then more prototypingSmall investments in prototyping early in a development program can equate to major savings of time and money later…  Prototyping in product design and development serves a range of different purposes. These range from assessing specific technical risks, through to problem-solving, trouble-shooting and quality assurance verification. At Bayly we urge you to utilise prototyping to reduce time to market, reduce risk and reduce cost. Bayly’s Prototyping services allow you to visualize and assess product designs before you invest in costly tooling and manufacturing. You can address and resolve critical development issues and risks through the use of Bayly’s latest tools, materials, processes and expertise. Our prototyping services include finishing, assembly, testing and comprehensive review of design based on individual project requirements. Call us today and find out how our prototyping services can help get your products to market faster.

|

The types of manufacturing processes that we use to make our prototypes for you are widely representative of the actual manufacturing processes that will eventually be used and include

|

+61 3 9413 9000