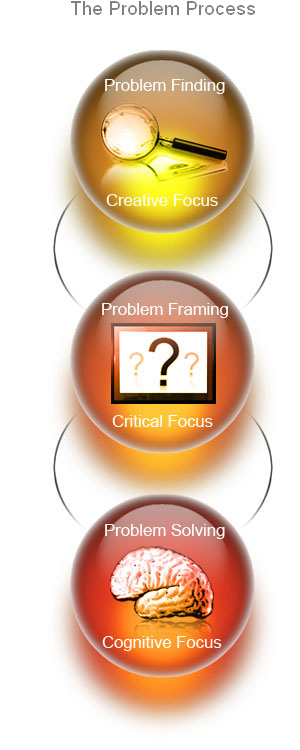

Problem Solving

People solve problems everyday and we all know people who are better at solving problems than others. There are times, for whatever reason, everyone needs help. At Bayly we have techniques that we have practised and skills we have honed that can be applied to solving just about any type of engineering problem.

Problems share some typical characteristics

- A lack of clarity of the situation

- Multiple goals

- Complexity – large number of items, interrelations and decisions

- Time considerations and unpredictability

Problem Solving After the fact

Problem solving is of crucial importance in when products or processes fail and so that corrective action can be taken to prevent further failures. Failure analysis involves tracing product defects and flaws and can be combined with the design and management of corrective action to prevent further failures. Failure analysis is a common technique used in forensic engineering as applied in the legal world when blame and cause are important issues. This is a way of managing problems as they arise.

Problem Solving Before the fact

Of more value, problem solving can be applied to a product or process prior to an actual failure; a potential problem can be predicted, analysed and mitigation applied so the problem never actually occurs. Our Failure Mode Effects Analysis (FMECA) process can be used to proactively reduce the likelihood of problems occurring. The FMECA framework can be applied to any product, process or service to predict and manage failures before they occur.

Problem Solving Techniques

At Bayly, we are experienced at applying a myriad of different problem definition, shaping and solving techniques;

- Modelling

- Simulation

- Brainstorming

- Cause & effect analysis

- Lateral thinking

- Failure and failure mode analysis

- Trial and error